Printing Blankets

The offset printing systems is comprised of the dampening, inking and image transfer system. Critical to the image transfer system is offset blanket technology. Image integrity, quick release, durability and longevity are all attributes that are important to the offset blanket system.

Coating

Much improvement added to blankets has massive importance in printing industry. The characteristics of its unique construction, which is based on the cord carcass, brings outstanding advantages: decreased use in the printing process or a 30% saving in comparison with standard offset printing blankets. The offset printing blanket is noted for outstanding dimensional stability, impact resistance, and excellent print quality also offset printing blankets is noted for outstanding dimensional stability, minimum loss in thickness, impact resistance, longer service life and excellent print quality. Designed and formulated for a wide range of sheeted presses for printing on paper/ carton stocks.

Coating blanket

|

CHARACTERISTICS |

ADVANTAGES |

|

Smoothly polished surface |

Offers even varnish film thickness with minimum pressure settings and optimum varnish transfer. |

|

Exceptionally stable pre-carcass ply |

Calibrated radial cord pre-carcass adds dimensional stability for precise register and reuse of blanket. |

|

Unique carcass |

Calibration of each blanket layer ensures deep stencil depth of min. 0.90 mm for cleaner profiles. Excellent flexibility for an easier press mounting. Clean stencil cutting with sharp edges by hand or CAD. Easy peeling for a quick, trouble-free preparation. |

Packaging

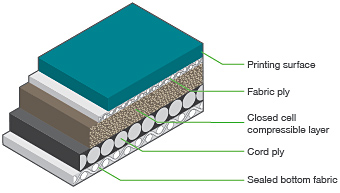

A unique high performance concept of the radial cord carcass now applied in a specifically designed compressible printing blanket for low speed commercial heatset presses and high quality sheetfed printing with a wide variety of inks.

|

CHARACTERISTICS |

ADVANTAGES |

|

Dimensional Stability |

Virtually no sinking or stretching giving the blanket an exceptional dimensional stability. Calibration of each blanket layer ensures good reproducibility and high quality throughout a blanket life. After mounting no need for further re-tensioning thus leading to a reduced down time. |

|

Closed Cell Compressible Layer |

New compressible layer coupled with a radial cord carcass improves durability, offers excellent shock absorption and rapid recovery. Resists solvent penetration, reduces the risk of delamination. A high overall rubber content of the Advantage Pearl favours lower heat build-up when compared to standard textile carcass blankets. |

|

Microground Printing Surface |

Specially formulated surface compound is specifically ground in order to ensure excellent ink transfer and dot reproduction on a wide range of paper qualities. Reduced paper linting contributes to reducing wash cycles. |

|

Sealed Bottom Layer |

Provides added protection against water and chemical penetration. |